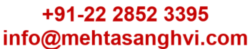

MWR-JGS Mini Grooving Tool

| CUTTING RANGE | FREE SPEED | POWER | TORQUE |

|---|---|---|---|

| Up to 101,6 mm | 100 Rpm | 1,3 Hp | 140 Nm |

| Up to 4” | 100 Rpm | 1,3 Hp | 105 Ft.Lbs |

BASIC DATA

- Air use: 55 cfm (1,3 m3/min)

- Body width: 2,32” (59 mm)

- Body height: 13,1” (335 mm)

- Body weight: 17,5 Lbs (8 kg)

First in the world, quick, powerful, yet handheld machine for serrating tube sheet in heat exchangers, boiler drums, FinFan coolers and other tubular vessels that need grooves in the tube sheet. Tool usues one cutting bit for cut any material tubes.

This unique system safely and quickly produces grooves in under 20 second for 1” tube.

Can be used as a tool for maintenance companies as well as the production tool with our dual pneumatic locking system and pneumatic cooling and lubricating module.

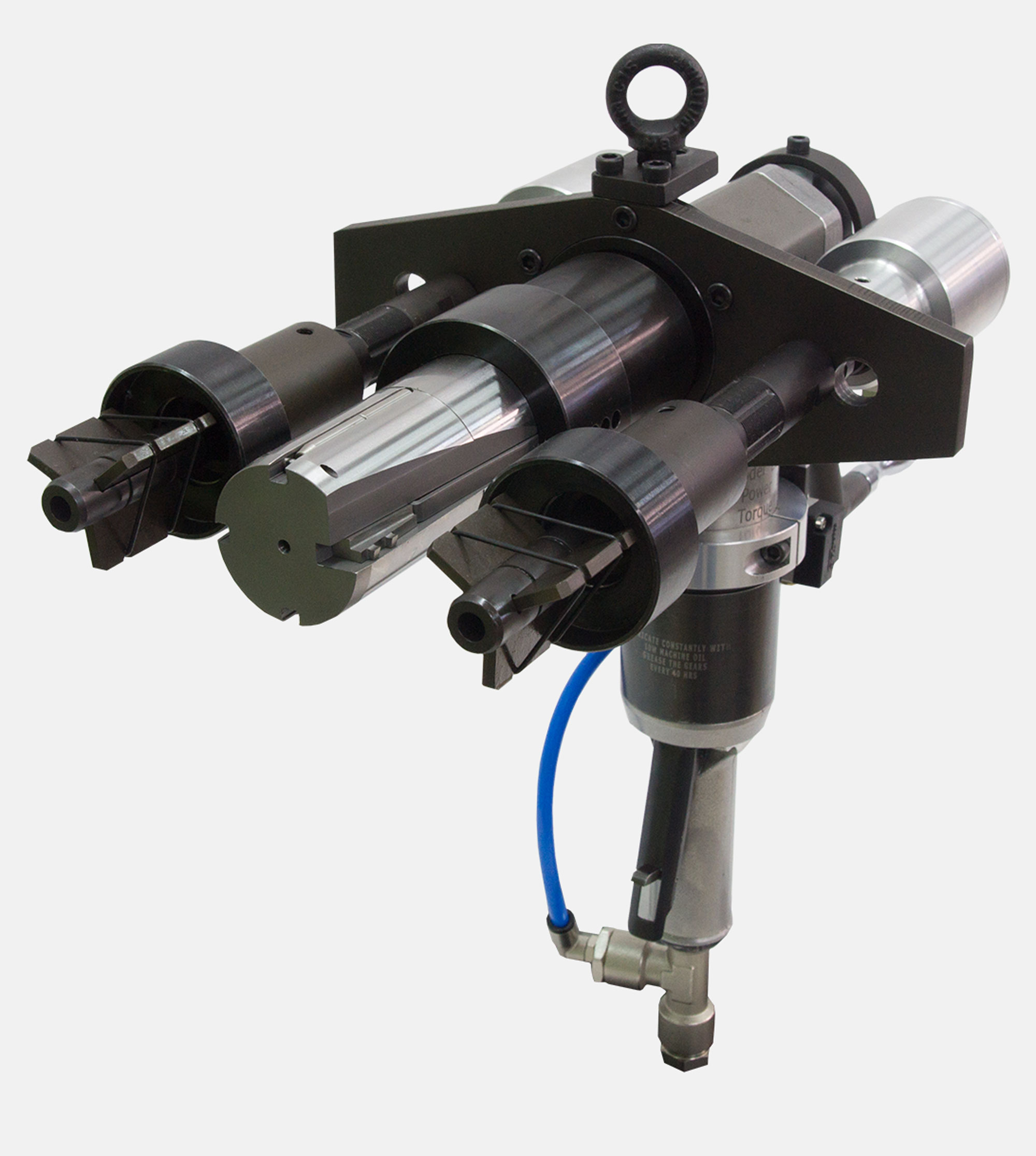

On regular tube sheet

On standard heat exchangers machine locks onto two shafts on the adjacent holes. The locking plate is manufactured according to the tube hole pitch to ensure precise tool alignment.

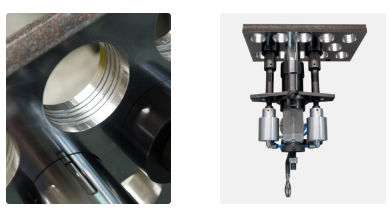

MWR-JGS reaction plates

Standard locking plate has 2 reaction shafts, located from each site of the spindle. We can also supply locking plate that has locking shaft located on one side of the spindle and can be rotated through 180 degrees to accommodate partition plates, channel heads etc.

Other features

Full range of the grooving tools from 1/2” to 4

The rollers over the circumference of the mandrel allow to achieve a perfect surface of the hole.

MWR-JGS E is the electric version of the Mini Grooving Tool. The standard machine covers the same tube sizes. The electric motor, made by Makita, has a 3 stage planetary gear box manufactured by KRAIS. It has variable speed control and produces enormous torque. It is interchangeable with our pneumatic drive and can be purchased at any time.

- Free Speed 120 RPM

- Power 1,3 Hp

- Torque 360 Nm (266 Ft.Lbs)

- Feed Stroke 25 mm (1”)

Grooving tools for MWR-JGS

Working ranges

| Tube Size | Tool Number | Tool Bit 1/8x1/4x1/8” | Tool bit 3x6x3 mm | Tool Bit Spring | Mandrel | Turning rols |

|---|---|---|---|---|---|---|

| 1/2” | JGS-MWR-127 | ST-5003-S | GS-206 | ST-5011 | GS-MWR-127 | - |

| 5/8” | JGS-MWR-158 | ST-6203-S | GS-306 | ST-6211 | GS-MWR-158 | - |

| 16 mm | JGS-MWR-160 | ST-6203-S | GS-306 | ST-6211 | GS-MWR-160 | - |

| 3/4” | JGS-MWR-190-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-190-R | STR-3-55 |

| 20 mm | JGS-MWR-200-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-200-R | STR-4-55 |

| 22 mm | JGS-MWR-220-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-220-R | STR-4-55 |

| 7/8” | JGS-MWR-222-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-222-R | STR-5-55 |

| 25 mm | JGS-MWR-250-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-250-R | STR-5-55 |

| 1” | JGS-MWR-254-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-254-R | STR-5-55 |

| 1-1/8” | JGS-MWR-285-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-285-R | STR-5-55 |

| 1-1/4” | JGS-MWR-317-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-317-R | STR-5-55 |

| 1-1/2” | JGS-MWR-381-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-381-R | STR-5-55 |

| 1-3/4” | JGS-MWR-444-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-444-R | STR-5-55 |

| 2” | JGS-MWR-508-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-508-R | STR-5-55 |

| 51” | JGS-MWR-510-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-510-R | STR-5-55 |

| 2-1/4” | JGS-MWR-751-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-751-R | STR-5-55 |

| 2-1/2” | JGS-MWR-635-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-635-R | STR-5-55 |

| 2-3/4” * | JGS-MWR-698-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-698-R | STR-5-55 |

| 3” * | JGS-MWR-762-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-762-R | STR-5-55 |

| 4” * | JGS-MWR-1002-R | ST-7503-S | GS-406 | ST-7511 | GS-MWR-1002-R | STR-5-55 |

Bevelling Machines

- Tube & Pipe Beveling Machines

- ACTP-1000 Automatic set for tube pulling

- Auto MiniMill

- Beveling heads, inserts and cutters

- HyperLathe

- HyperMill 56

- HyperMill 76

- MWR Mini Wall Reducer

- MiniDril

- MiniLathe

- MiniMill 101

- MiniMill 201

- MiniMill 300FF

- MiniMill 300GFF

- MiniMill 301LP

- MWR-JGS Mini Grooving Tool

- PipeLathe 40

- PipeMill

- PrepMill

- SmartMill-7

- TES Mini 2

Rolling Controls

- Rolling & Expanding Tools

- Boiler Tube Expanders

- Condenser & Heat Exchangers Tube Expanders

- Rolling Motors

- Digital Controllers