HyperLathe

- Powerful 3.5 HP pneumatic drive generating 7500 Nm (5,530 ft.lbs) torque on the cutter blade. Variable speed control 0-10 rpm.

- No need for extra gear box that reduces the rpm and multiplies the torque. It comes as standard!

- One piece locking shaft with build in jaws, eliminates the issue of broken or loosening retaining springs and o-rings.

- One mandrel covers complete working

range.

- Innovative 6 point locking system assures maximum stability during all machining operations.

- Only one mandrel and 10 Jaw sets needed to cover machines entire range.

- Self-centering shaft with build in jaws.

- Wide Clamps produce superior clamping force for chatter free end preps.

- Fully portable for on-site and Fab-shop work.

- Available for sale or rent.

Standard working range

| APPLICATION RANGE | LOCKING RANGE (ID) |

| 101 – 508 mm | 100 - 460 mm |

| 4,0 – 20,0” | 3,937 - 18,110” |

Motor parameters

| FEED STROKE | FREE SPEED | POWER | TORQUE | ||

| 60 mm | 2,4” | 10 Rpm | 3,5 Hp | 7500 Nm | 5530 Ft.Lbs |

| Air use: | 85 cfm | 2,8 m3/min | Air pressure: | 90 PSI | 6,2 Bar |

| Body dimensions | 31 x 17 x 16” | 800 x 425 x 400 mm | Body weight: | 185 Lbs | 84 kg |

Advantages of hyperlathe

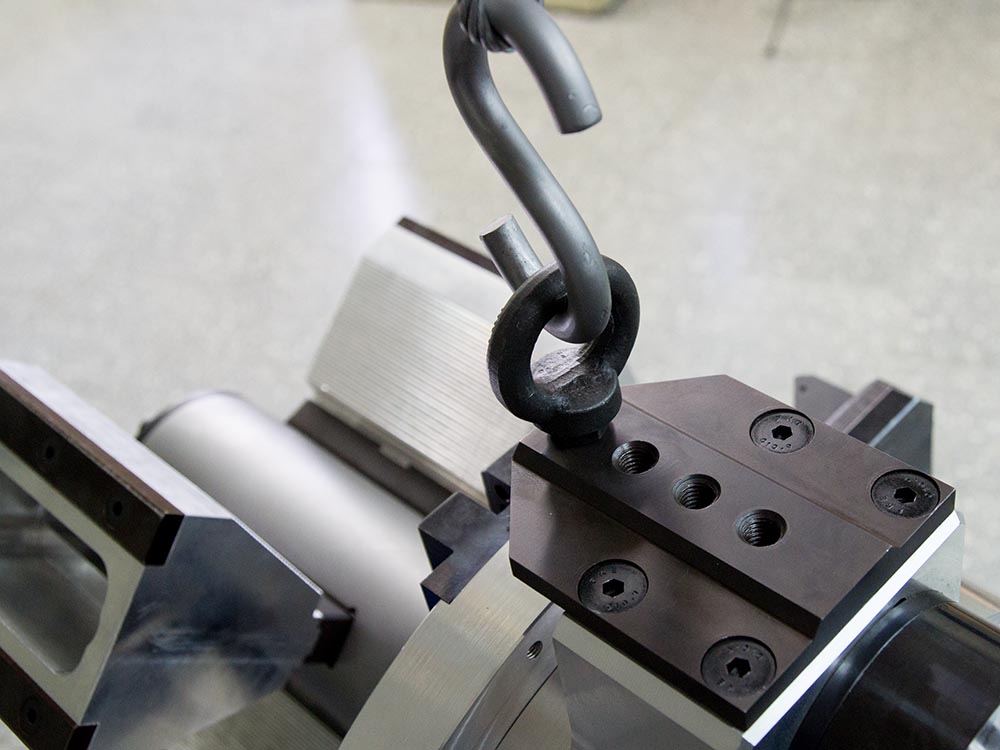

UNIQUE SHAFT DESIGN 70 mm (2,75”) shaft, assures rigidity when machining heavy wall pipe. The jaws are fully contained within the shaft with no need for retaining springs or O-rings that easily brake or get lost.

70 mm (2,75”) shaft, assures rigidity when machining heavy wall pipe. The jaws are fully contained within the shaft with no need for retaining springs or O-rings that easily brake or get lost.

70 mm (2,75”) shaft, assures rigidity when machining heavy wall pipe. The jaws are fully contained within the shaft with no need for retaining springs or O-rings that easily brake or get lost.

70 mm (2,75”) shaft, assures rigidity when machining heavy wall pipe. The jaws are fully contained within the shaft with no need for retaining springs or O-rings that easily brake or get lost.POWERFUL MOTOR UNIT Powerful and efficient drives dedicated for our Lathe series beveling machines. 11 rpm and 3850 Nm (2840 Ft.Lbs) torque on the cutter blade is a standard feature.

Powerful and efficient drives dedicated for our Lathe series beveling machines. 11 rpm and 3850 Nm (2840 Ft.Lbs) torque on the cutter blade is a standard feature.

Powerful and efficient drives dedicated for our Lathe series beveling machines. 11 rpm and 3850 Nm (2840 Ft.Lbs) torque on the cutter blade is a standard feature.

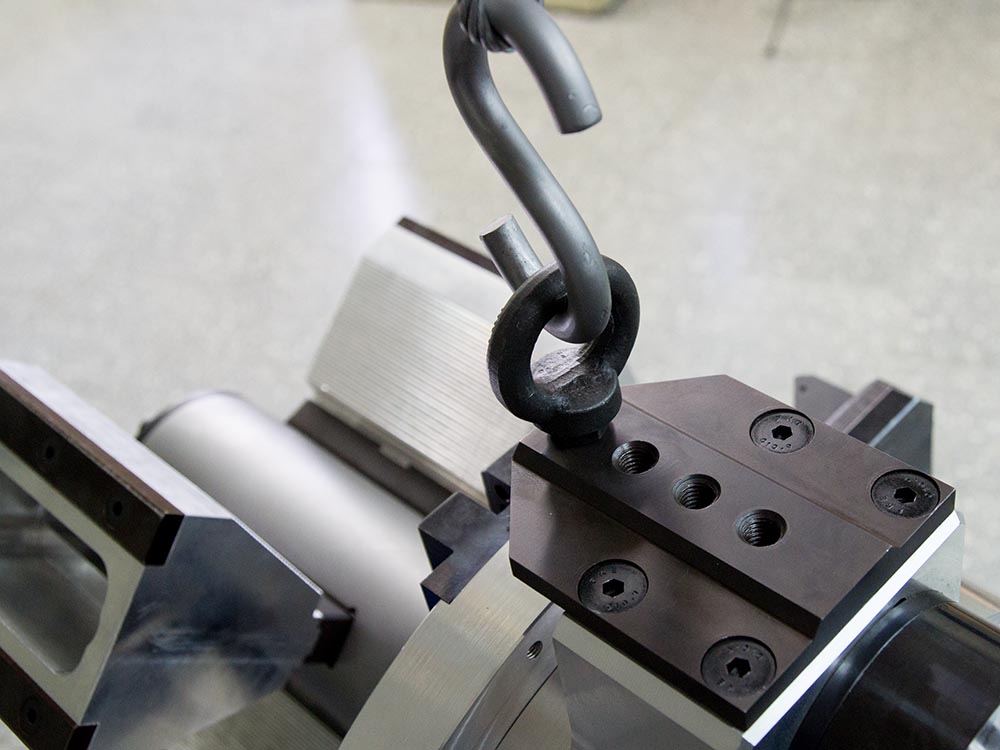

Powerful and efficient drives dedicated for our Lathe series beveling machines. 11 rpm and 3850 Nm (2840 Ft.Lbs) torque on the cutter blade is a standard feature.6 POINTS LOCKING JAWS The innovative, 6 points jaws, effectively lock the machine within the pipe, allowing safe, efficient and smooth processing of the tube end.

The innovative, 6 points jaws, effectively lock the machine within the pipe, allowing safe, efficient and smooth processing of the tube end.

The innovative, 6 points jaws, effectively lock the machine within the pipe, allowing safe, efficient and smooth processing of the tube end.

The innovative, 6 points jaws, effectively lock the machine within the pipe, allowing safe, efficient and smooth processing of the tube end.HEAVY DUTY PENDANT Machine is equipped with a heavy duty pendant. This can be attached to both sides of the motor for operator convenience.

Machine is equipped with a heavy duty pendant. This can be attached to both sides of the motor for operator convenience.

Machine is equipped with a heavy duty pendant. This can be attached to both sides of the motor for operator convenience.

Machine is equipped with a heavy duty pendant. This can be attached to both sides of the motor for operator convenience.Bevelling Machines

- Tube & Pipe Beveling Machines

- ACTP-1000 Automatic set for tube pulling

- Auto MiniMill

- Beveling heads, inserts and cutters

- HyperLathe

- HyperMill 56

- HyperMill 76

- MWR Mini Wall Reducer

- MiniDril

- MiniLathe

- MiniMill 101

- MiniMill 201

- MiniMill 300FF

- MiniMill 300GFF

- MiniMill 301LP

- MWR-JGS Mini Grooving Tool

- PipeLathe 40

- PipeMill

- PrepMill

- SmartMill-7

- TES Mini 2

Rolling Controls

- Rolling & Expanding Tools

- Boiler Tube Expanders

- Condenser & Heat Exchangers Tube Expanders

- Rolling Motors

- Digital Controllers