MWR Mini Wall Reducer

| CUTTING RANGE | FREE SPEED | POWER | TORQUE |

|---|---|---|---|

| Up to 31,75 mm | 100 Rpm | 1,3 Hp | 140 Nm |

| Up to 1,250” | 105 Ft.Lbs |

- Air use: 55 cfm / 1,3 m3/min

- Body width: 2,32”/ 59 mm

- Body height: 13,1” / 335 mm

- Body weight: 9 Lbs / 4,5 kg

First in the world for the quick and efficient spot reduction of heavy wall carbon and alloy tubing in refinery heat exchangers, FinFan coolers and other tubular vessels. This unique system safely reduces the tube wall in the form of a slot so that a One Revolution Tube Cutter can then pierce and cut a ventilation slot at the appropriate 90 or 180 degrees, prior to plugging the leaking tube. Mini Wall reducer uses one cutting bit and can be used for any material tubes.

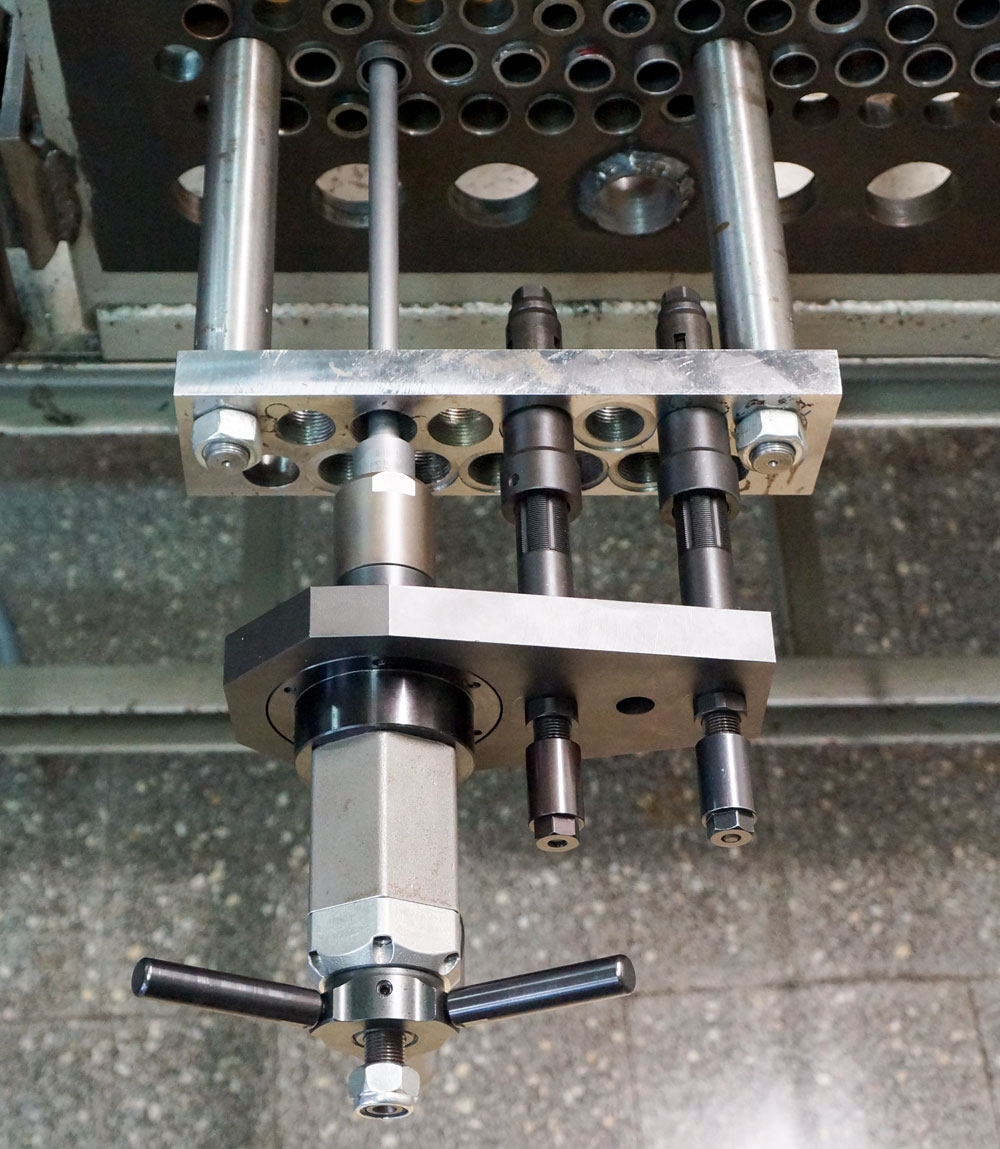

MWR on regular tube sheet

On standard heat exchangers machine locks onto two shafts on the adjacent holes. The locking plate is manufactured according to the tube hole pitch to ensure precise tool alignment.

MWR on FinFan Header mock-up

We recommend the use of dedicated locking plates to suit specific tube sheet or water box header pitch.

MWR on FinFan cooler

MWR with optional shafts for FinFan coolers lock in the plug holes with special jaws that do not damage the thread.

Locking plate has 2 reaction shafts and can be rotated through 180 degrees to accommodate partition plates, channel heads etc.

MWR E

MWR E is the electric version of the MWR and covers the same tube sizes. The electric motor, made by Makita, has a 3 stage planetary gear box manufactured by KRAIS. It has variable speed control and produces enormous torque. It is interchangeable with our pneumatic drive and can be purchased at any time.

- Free Speed: 120 RPM

- Power: 1,3 Hp

- Torque: 360 Nm (266 Ft.Lbs)

- Feed Stroke: 25 mm (1”)

PTWR for Mini wall reducer

ORTCS for mini wall reducer

Working ranges

ORTCS are recommended for hand use only. No Impact wrenches or other high torque tools are to be used in its operation. These tools are ideal for puncturing tubes prior to tube plugging. This tool is intended for use on all non-ferrous materials and some ferrous tubes.

Cutter Blade: Recommend quantity of 1 per 100 brass or copper tube cuts or 1 per 50 tube cuts of other materials.

Cutter Pin: Recommend quantity of 1 pin for every 2 cutter blades.

We recommend the use of a high quality cutting oil to maximize the life of the cutter bit.

Bevelling Machines

- Tube & Pipe Beveling Machines

- ACTP-1000 Automatic set for tube pulling

- Auto MiniMill

- Beveling heads, inserts and cutters

- HyperLathe

- HyperMill 56

- HyperMill 76

- MWR Mini Wall Reducer

- MiniDril

- MiniLathe

- MiniMill 101

- MiniMill 201

- MiniMill 300FF

- MiniMill 300GFF

- MiniMill 301LP

- MWR-JGS Mini Grooving Tool

- PipeLathe 40

- PipeMill

- PrepMill

- SmartMill-7

- TES Mini 2

Rolling Controls

- Rolling & Expanding Tools

- Boiler Tube Expanders

- Condenser & Heat Exchangers Tube Expanders

- Rolling Motors

- Digital Controllers