Bevelling Machines With Automatic Feeding

Art. 910

Description :

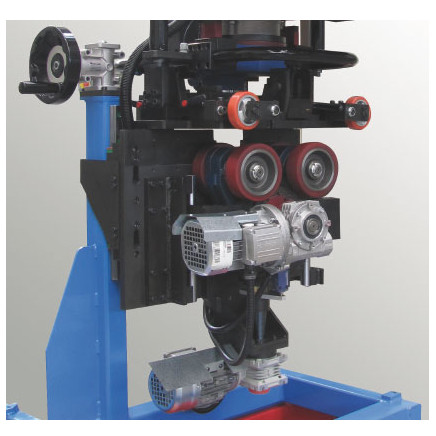

- Frame in steel and aluminum casting.

- Hardened work table with sliding rollers.

- Motorized feeding with four polyurethane wheels (90 shore).

- X, Z and A angle axis adjustment.

- Trolley complete with height adjustment devices, chip protection, chip box, and swivel wheels with brake.

- Possibility to work with the trolley lifted in the presence of irregular floor. Possibility to work also without trolley.

Performances :

| ART. 910 | |

|---|---|

| Motor power | Trifase 230/400 Volt, 4kw, 50/60 Hz, 4 poli |

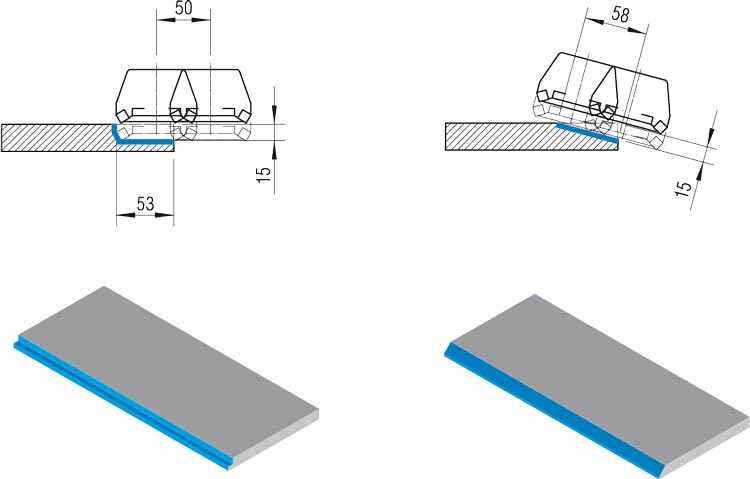

| Width bevelling (X axis) | 53 mm |

| Depth bevelling (Z axis) | 15 mm |

| Chamfering angle | From 90° to 75° |

| Plate thickness | From 8 mm to 100 mm |

| Cutter | Ø 63 mm Z 7 |

| Cutter speed | 900 RPM |

| Chamfering speed | from 0 to 1 mt/min |

| Working height | 930 mm ÷ 1120 mm |

| Working direction | |

| Dimensions | 760 x 750 x h 2100 mm |

|

Application |

Steel, stainless steel, cast iron, aluminium, alloy titanium, hardox, super duplex and so on |

| Weight | Kg. 390 |

| Packing dimension | mm 2150x1150x1100 h - Kg. 455 |

(*) Different voltage available on request.

Cutter :

| Sketch |  Art. 844 |

| Diameter | Ø63 mm H=40 mm Ø=22 mm (1x) |

| Insert | ISO SDHT09 12,7x12,7 Thickness 4,76mm |

| N° | 7 |

| Material | WIDIA |

| Insert code | 865/R |

| Option | For light alloy 865/A |

Bevelling Performances :