Flange Management

Flange Management is the package of services that provides the best possible chance of achieving a leak-free tube&pipe connections. Correct assembly of a critical flange connection requires the highest quality in terms of machining and production of flanges. KRAIS Tube&Pipe Tools has a growing family of best tools for this kind of job!

MMFM - Mini FlangeMill

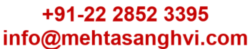

Compact and light weight flange milling machine – one of the most compact designs on the market today.

- Low clearance.

- Flat and raised face flanges

- Single line, true gramophone groove with 50 grooves per 1” to comply with ASME B46.1 code

- Pneumatic drive 1,3 Hp or 750 W electric with multiple planetary gear box

- Stainless steel body to stiffen the machine base

- Rigid construction aluminium facing head, supported by multiple bearings

- Solid locking mandrel shaft and rigid mounting jaw set

- Hardened and ground tool slides for precision

QUALITY COMPONENTS

- Pneumatic motor comes complete with filter, lubricator and flow control.

- Compact, low-profile drive system engineered for superior power to weight ratio.

- Features rugged main body, heavy-duty bearings, sealed lubrication, and rigid mounting system.

BASIC DATA

- Air use: 55 cfm (1,3 m3/min)

- Weight: 23 Lbs (10,43 kg)

- Height: 19,29″ (490 mm)

- Length: 16,33″ (415 mm)

- Swing diameter: 12,20″ (310 mm)

Working ranges :

| FLANGE FACING | PIPE FACING (SINGLE POINT) |

MOUNTING (ID) | VERTICAL FEED STROKE | MACHINING FEED RATE | POWER |

|---|---|---|---|---|---|

| 1,37 – 10″ | 2 – 10″ | 1 – 5,9″ | 0,5″ | 0,019″ | 1,3 Hp |

| 35 – 254 mm | 51-254 mm | 26 – 150 mm | 13 mm | 0,5 mm |

Tool holders :

MMFM is a low clearance flange facing machine. To achieve these multiple tool holders are required to cove full range, below table specifies machining range of each holder.

| TOOL HOLDER | [mm] | [inch] |

|---|---|---|

| MMFM-125250 | 125 – 250 mm | 4,92 – 9,85″ |

| MMFM-85210 | 85 – 210 mm | 3,35 – 8,27″ |

| MMFM-37160 | 37 – 160 mm | 1,45 – 6,30″ |

MMFM Features :

Single line gramophone groove (50 grooves per 1 inch)

Single line gramophone groove (50 grooves per 1 inch) Safety first! Handguard to protect against the accidental impact of the rotating head.

Safety first! Handguard to protect against the accidental impact of the rotating head. Handy depth feed locking system to prevent accidental movement of the handle during flange processing.

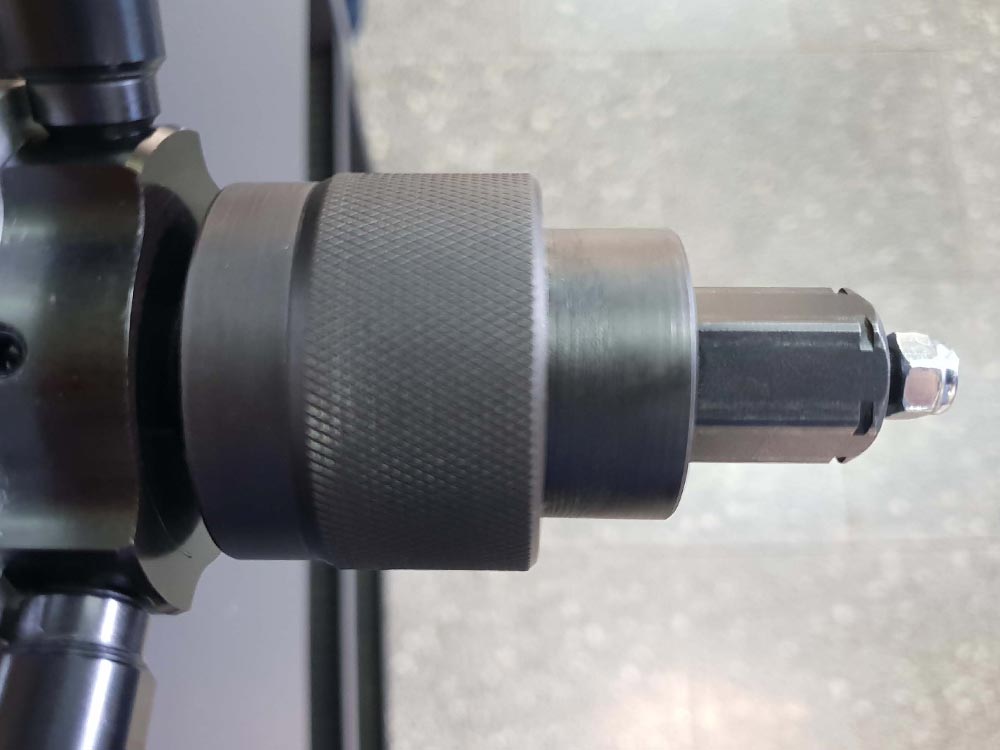

Handy depth feed locking system to prevent accidental movement of the handle during flange processing. Convenient and easy to read gauge in metric and imperial scale allowing adjustment of the working range before mounting on the flange.

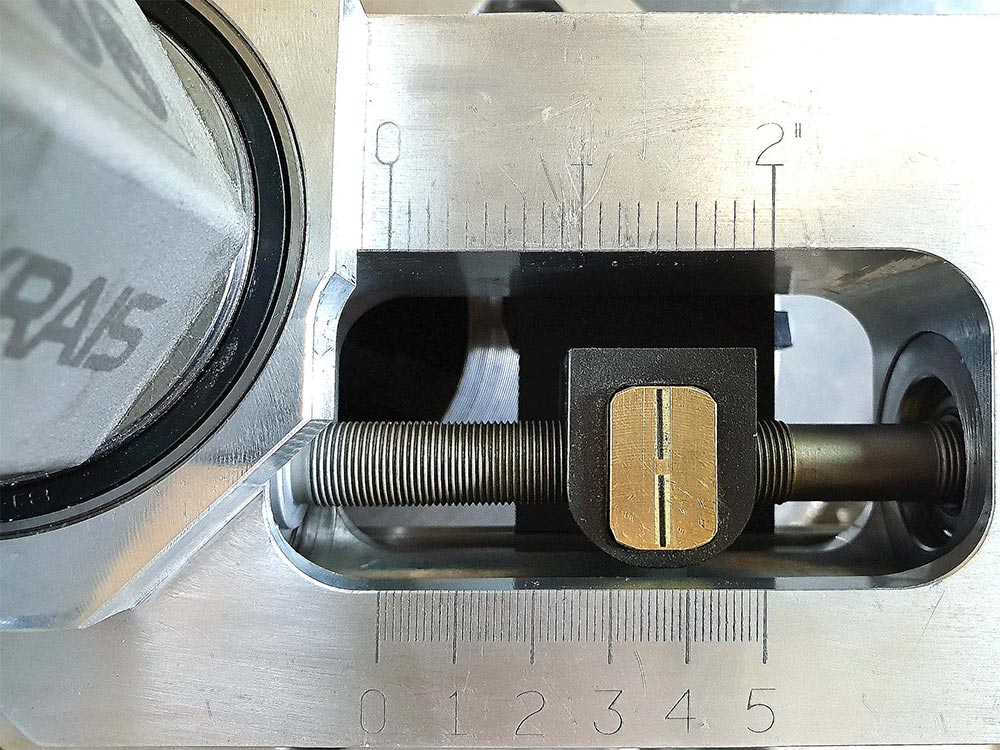

Convenient and easy to read gauge in metric and imperial scale allowing adjustment of the working range before mounting on the flange. The graduation of the tool setting to the desired depth of cut.

The graduation of the tool setting to the desired depth of cut.MMFM Options :

Feed screw

The machine comes standard with 50 grooves per inch feed screw and nut. Optional feed screw/nut are available with 68 and 101 grooves per inch.

The machine comes standard with 50 grooves per inch feed screw and nut. Optional feed screw/nut are available with 68 and 101 grooves per inch.MMFM-E

An electric version of MMFM. A standard machine covers the same flange sizes and comes with the same cutting head.

The electric motor, made by Makita with 3 stages planetary gearbox made by KRAIS has variable speed control and produce enormous torque. Is interchangeable with pneumatic drive and can be purchased separately at any time.

An electric version of MMFM. A standard machine covers the same flange sizes and comes with the same cutting head.

The electric motor, made by Makita with 3 stages planetary gearbox made by KRAIS has variable speed control and produce enormous torque. Is interchangeable with pneumatic drive and can be purchased separately at any time.Free Speed: 115 RPM Power: 750 W Torque: 360 Nm (266 Ft.Lbs)

Battery option

The machine is also available with a portable electric drive 18 Volt 5.2 Ah 93.6 Wh Li-Lon battery. The machine can operate up to 15-20 minutes on one battery.

The machine is also available with a portable electric drive 18 Volt 5.2 Ah 93.6 Wh Li-Lon battery. The machine can operate up to 15-20 minutes on one battery.Machining itself of one flange takes about 3-4 minutes of motor operation, so the operating time on one battery may suffice on 3-4 flanges. It is possible to have many charged batteries. Comfortable and easy to use in any place where compressed air and electricity is not available or even impossible to use as for example oil refinery.